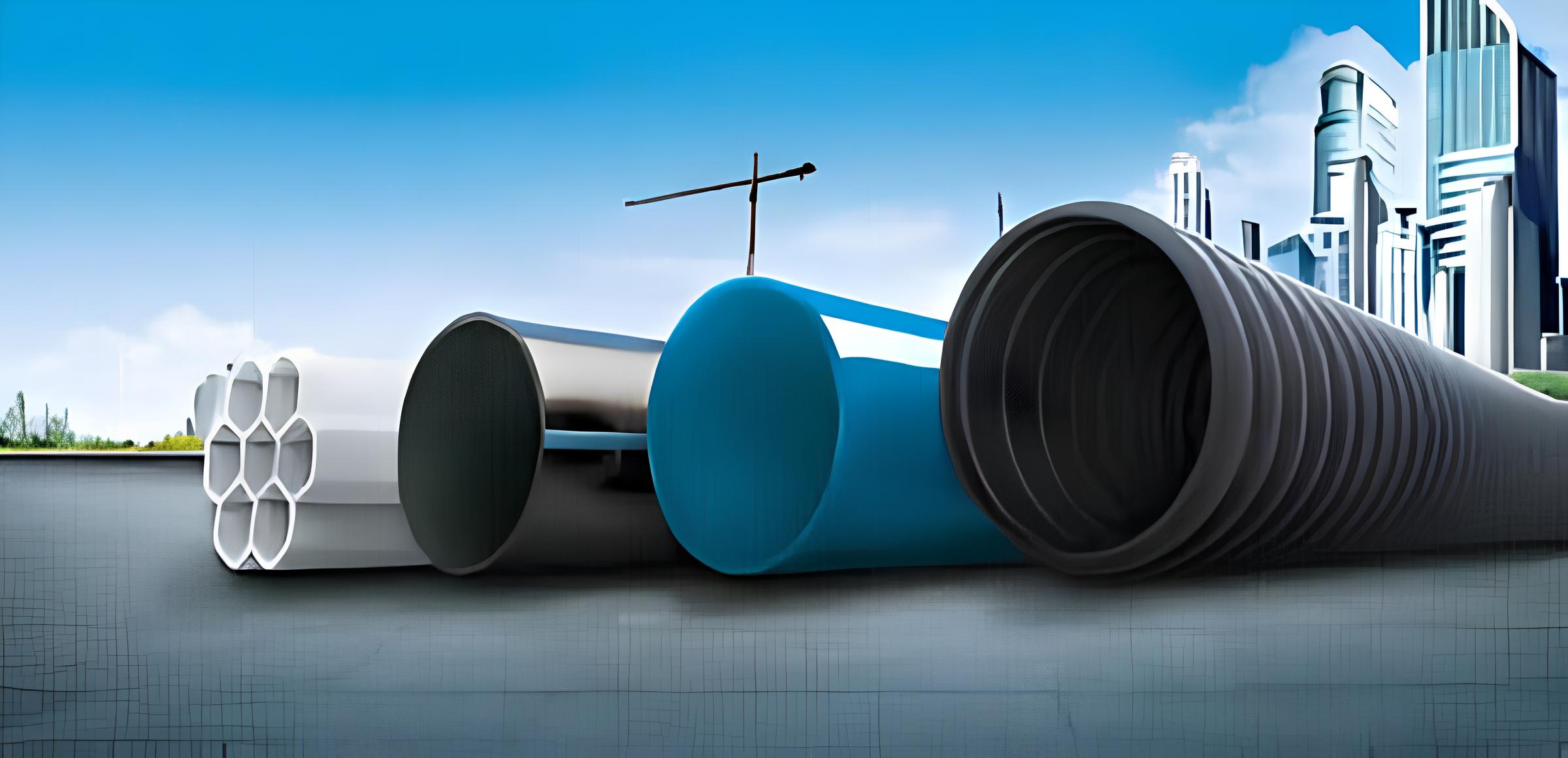

Plastic pipe systems are one of the most important technical systems in today's life. A tremendous amount of plastic is being processed daily for use in households and industries, owing to the superior qualities of plastics over conventional material. Polymeric materials are used in the production of plastic products applying various processing techniques including extrusion, spinning, injection molding, thermoforming, and casting. The raw materials used to produce plastics today are mostly found in the natural world, cellulose, coal, natural gas, salt, and crude oil. Plastics will increasingly be made from waste, renewable materials, or CO2. They are used in households, Packaging, Healthcare, Mobility and Transport, Electronics, Agriculture, Sports and Leisure Equipment, Building, Construction, and Industry areas.

Acrylonitrile Butadiene Styrene (ABS): ABS pipes are softer than PVC pipes, but they are also more durable. Due to their durability, ABS pipes are best used underground, where they can withstand freezing temperatures, and in sewer systems. It is commonly used as a sanitary ware downpipe, gas transmission pipe, and high-corrosion industrial pipeline abroad. A domestic pipe is generally used for indoor cold and hot water pipes, dosing pipes for water treatment, and industrial pipelines with corrosive effects.

Polypropylene (PP): This plastic material is a thermoplastic polymer and the world’s second-most widely produced synthetic plastic. Its widespread use and popularity are undoubted because polypropylene is one of the most flexible thermoplastics on the planet. Although PP is stronger than PE, it still retains flexibility. It will not crack under repeated stress. Durable, flexible, heat-resistant, acid-resistant, and cheap, polypropylene sheets are used to make laboratory equipment, automotive parts, medical devices, and food containers. It makes lunch boxes, margarine containers, yogurt pots, syrup bottles, and prescription bottles. Plastic bottle caps are often made from PP.

PVC (Polyvinyl chloride): PVC plastic, also known by its full name (polyvinyl chloride), is one of the perfect materials for pipe processing. PVC plastic pipe is known as the type of pipe that plumbers love most in a variety of projects. PVC pipe is inherently hard, and durable and can be applied in many different environments including: installing drainage pipes, civil water supply pipes, irrigation pipes, or even pipes conducted under high-pressure conditions or underground. PVC material helps plastic pipes resist a variety of external agents such as corrosive acids, tree roots, and some abrasive substances. It is well-known for its ability to blend with other materials. For example, PVC sheets are a foamed polyvinyl chloride material that is ideal for products like kiosks, store displays, and exhibits. The rigid form of PVC is commonly in construction materials, doors, windows, bottles, non-food packaging, and more. PVC plastic pipe is super durability, has high corrosion resistance, shortened installation time, is lightweight, easy to mold, is a reasonable price, and especially they are also very environmentally friendly.

CPVC — Chlorinated Poly (Vinyl Chloride): CPVC is a rigid thermoplastic pipe and fitting material made when PVC is treated with additional chlorine. One of the benefits of CPVC comes from the added chlorine, which adds additional heat capability and also makes it resistant to damage from highly chlorinated or aggressive water. CPVC pipe is available in nominal sizes from 1/2" to 24" and is approved in all model plumbing and mechanical codes across the United States and Canada. In addition, CPVC pipe and fittings from select manufacturers are listed for light hazard fire sprinkler systems, as defined in NFPA 13, 13R, and 13D standards. This material is also used for Hot and cold water plumbing distribution, residential and commercial, reclaimed water piping, Chilled water piping, Hydronic piping and distribution, and many industrial and process piping applications.

FRP (Fibres Reinforced Polymer): FRPs comprise composite materials that have high-strength fibers which are typically included in a polymer matrix. Their high strength and lightweight nature are useful in both commercial and engineering applications. Increasingly, they are increasingly used to replace traditional materials such as wood and metals such as steel, iron, and aluminum. FRPs are a composite of materials that consist of a polymer matrix blended with a reinforcing material such as fibers. In general, the fibers can either be fiberglass, aramid, basalt, or carbon, with paper or asbestos. The resulting products are typically semi-rigid plastic products.

HDPE (High-density polyethylene): HDPE material is known as high-density polyethylene made from petroleum. Thanks to its high density in structure, HDPE plastic pipe has become one of the ideal choices for many different uses. The applications of HDPE are very diverse, including the production of cosmetic bottles, water bottles, containers, and even pipe installation. Regarding pipe production, HDPE plastic pipe is one of the popular materials in most industrial and infrastructure construction fields. HDPE plastic pipe plays a role in applications such as drainage pipes, domestic water pipes, firefighting system supply lines, rural irrigation, gas pipes, etc. It is easy to come across HDPE plastic pipes from industrial parks, and residential areas to public pipeline systems. HDPE pipe brings outstanding benefits to projects such as hardness, high resistance to most adverse impacts, lighter and easier to transport, and high resistance to freezing. They are very durable, helping to limit waste released into the environment.

LDPE (Low-density polyethylene): LDPE is a softer, clearer, more flexible version of HDPE—and it has its own strengths as well. It's often used as a liner inside juice and milk cartons, and it's used in corrosion-resistant work surfaces and other products, such as six-pack rings and plastic wrap. Lightweight plastic film, like a lot of LDPE applications, is lighter and more efficient than many alternatives, which helps us shrink our environmental footprint by reducing waste, energy use, and carbon emissions. It is mostly used as bags for groceries, newspaper delivery, dry-cleaning, bread, beverage cups, LDPE sheets, plastic wraps, and so on, plus product overwraps, bubble wrap, and cereal box liners. there are many industrial and agricultural uses, particularly plastic film and packaging to protect all sorts of products. Manufacturers commonly use LDPE in plastic bags and flexible packaging. It is known for being flexible, but recycling it is more difficult than HDPE.

Due to its inherent benefits, Plastic pipes are widely used in the water and food industry for transferring drinking water, wastewater, irrigation, chilled water systems, chemicals, heating fluid, cooling fluids, foodstuffs, etc.

The plastic industry is at a crossroads, with sustainability driving new technologies and policies. Consumer awareness and regulatory changes will likely shape the future landscape of plastic production and disposal.

Plastic pipe production materials on the market are increasingly upgraded. To choose a suitable plastic pipe, you need to consider many factors about material parameters, material properties, and properties of the material that will be transported in the pipe. Careful consideration and selection of a suitable plastic pipe will help manufacturers increase the performance of the plastic pipe system and minimize damage during system operation.